principle of irradiation

Writer: Sterilization Time: 2020-09-02 Browse: 581 ℃

What is the principle of irradiation

Principle of electron beam irradiation:

1. Direct accelerator: the electron is accelerated by the potential difference between the anode and cathode (release energy 5MeV)

2. Spiral accelerator: electrons are accelerated by the energy released by the electromagnetic field repeatedly applied by radio frequency (release energy > 10 MeV), thus releasing continuous energy.

Electron beam radiation (e-beam)

-

1. Electron beam (e-beam) radiation is a kind of ionization energy, which is characterized by low penetration and high dose rate. It has the best performance and short irradiation time for products with low density and uniform packaging. Wei

-

2. Some materials can produce induced radioactivity, such as stainless steel (very weak), flavonoids (very weak), especially tantalum (strong)

-

3. Electron beam radiation is widely used in the modification of plastics and other materials to modify or enhance their properties

What is the principle of cobalt-60 sterilization

1. At present, the common radiation sources are cobalt-60 and cesium-137. In the process of their decay, gamma rays are produced with the wavelength below 4 × 10-3 nm.

2. Gamma ray has high energy, which can excite and ionize the atoms and molecules in the irradiated material, and then produce a series of direct and indirect physical, chemical and biological reactions. These reactions lead to the complex decomposition and polymerization of biomolecules, which destroy and change the internal structure (especially DNA) of biomolecules, so as to inhibit or kill microorganisms.

What are the characteristics of Co-60 irradiation

Co-60 irradiation has the characteristics of deep penetration and low dose rate, and the temperature effect is very small. It can even handle high density products

-

1. Packaging integrity: radiation penetration is strong, no need for penetrating packaging materials. There is no requirement for pressure or vacuum.

-

2. Simple, reliable and immediate release: when gamma radiation is used, time is the only variable that needs to be controlled, so the possibility of deviation is minimal. After confirming the radiation dose used, the product can be released for transportation.

-

3. No residue, no radioactivity: gamma rays are pure energy. They don't produce residues, and they don't have enough energy to produce radiation.

Mechanism of radiation sterilization

The effects of radiation on food can be divided into primary and secondary. The primary is the ionization and chemical action of microbial intercellular substance after being irradiated by high-energy electron rays, and the secondary is that water produces various free radicals and hydrogen peroxide through radiation and ionization, and then reacts with other substances in cells. These two effects will hinder all activities in microbial cells, leading to microbial cell death. The irradiation dose for complete sterilization is 25 ~ 50kgy, which aims to kill all microorganisms except bacillus. The radiation dose of disinfection and sterilization is 1 ~ 10kGy, the purpose of which is to kill non spore producing pathogens in food, reduce microbial contamination and prolong the storage period. In a word, different radiation dose and electron energy should be controlled for different microorganisms.

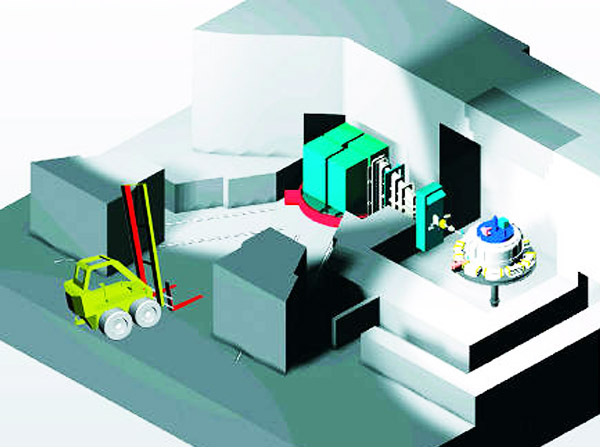

Basic principle: there is a strong cobalt-60 radioactive source in it, and a conveyor belt device is installed around it; with the continuous movement of the conveyor belt, the articles that need to be disinfected slowly pass through the side of the cobalt-60 source, so as to achieve the purpose of sterilization.

Main application fields of irradiation equipment

1. Using electron beam to irradiate the thyristor and chip can change the performance of the optimized products.

2. Degradation of chloramphenicol residues in aquatic products and bee products, up to the export country's pesticide residue health standards.

3. Preservation of agricultural and sideline products, food, sea and aquatic products. The purpose of sterilization, insecticidal, germination inhibition and shelf life extension was achieved.

4. Disinfection and sterilization of disposable medical and health products (medical dressing, gauze, gloves, surgical medical instruments, etc.)

5. The use of electron beam in sterilization of Chinese patent medicine and health care products can effectively kill all kinds of harmful bacteria in Chinese patent medicine and health care products, so as to meet the practical health requirements.

6. Topaz, pearl, crystal color, improve product quality, increase product added value.

7. Degradation of polymer materials. PTFE was degraded by electron beam to obtain micron and nanometer ultrafine powder.

8. Sterilization of pet feed. Electron beam can effectively kill all kinds of bacteria in pet feed, especially Salmonella. So as to reach the hygienic standard of pet eating.

9. Sterilization of all kinds of toys. In order to ensure that all kinds of toys in the production process of bacterial pollution will directly affect the health of children, it is necessary to carry out electron beam sterilization, so as to meet the health requirements.

10. Harmful bacteria in cosmetics raw materials and bacteria produced by pollution in cosmetics production will bring potential risks to the skin, and high temperature sterilization will destroy the characteristics of cosmetics and affect its quality. Electron beam sterilization is carried out at room temperature, which is an ideal sterilization method for cosmetics that are not resistant to high temperature.

11. Commodity maintenance (mould proof). After being irradiated by electron beam, all kinds of commodities can play the role of mould proof, so as to achieve the maintenance of commodities.

What is theIrradiation technology?

Irradiation technology is to irradiate sterilized articles by gamma ray produced by radioisotope (Co-60) and high-energy electron beam or X-ray produced by accelerator to change the physical properties and chemical composition of sterilized articles, so as to achieve the purpose of disinfection and sterilization.

In the irradiation station, the packaging boxes containing medical devices enter the irradiation room one after another with mechanical conveyor belt. After a short period of radiation or electron beam irradiation, the conveyor belt will automatically export the goods to the irradiation room for unloading, and then the sterilization process is completed.

In this way, the penetration of sterilization is relatively strong, which can eliminate all kinds of microorganisms in the box without unpacking. Generally, the radiation sterilization can be completed after the four sides of a box of protective clothing are irradiated by cobalt 60 or electron accelerator for 15 minutes.

characteristic

Irradiation technology has a good reputation in the field of sterilization, fast speed is only one of its characteristics, in addition, it is also safe, environmental protection, green, reliable.

The first is to eliminate radioactive sources. The irradiation sterilization place is usually the irradiation room specially built by the manufacturer. The cobalt 60 radioactive source will be sealed in the double-layer stainless steel container, and the product will be loaded in the special irradiation container. There is a certain distance between the two, so the product is only irradiated by the penetration of radiation, and will not be contaminated by radioactive substances.