What is gamma irradiation sterilization

Gamma sterilization uses a radioactive source, typically Cobalt-60 (60Co), which emits high energy gamma rays. Ionizing radiation can modify physical, chemical, and biological properties of materials. Currently, principal industrial applications of radiation are for sterilization of healthcare products (including pharmaceuticals), irradiation of food and materials modification (such as polymer cross-linking).

gamma irradiation is effective for sterilization

gamma irradiation is effective for sterilization because it quizlet.

Gamma Radiation causing electron displacement within. These reactions, in turn, generate free radicals, which aid in breaking chemical bonds. Disrupting microbial DNA renders any organisms that survive the process nonviable or unable.

Gamma radiation does have some significant advantages over other methods of producing sterile product. These benefits include: better assurance of product sterility than filtration

and aseptic processing; no residue like EtO leaves behind; more penetrating than E-beam;low-temperature process and simple validation process.

Gamma ray dose

-

The dose of selective irradiation sterilization is generally set below 5kGy, and its main purpose is to inhibit the growth and reproduction of spoilage microorganisms and increase the period of frozen storage.

-

The dose range of targeted irradiation sterilization is 5kGy.

-

Radiation complete sterilization is a high-dose radiation sterilization method, the dose range is 10-60kGy.

gamma irradiation dose for sterilization.A certain dose of gamma rays may take a period of time, ranging from minutes to hours, depending on the thickness and volume of the product. Beam irradiation can produce the same dose in a few seconds, but can only make the beam smaller. According to their different action mechanisms, these sterilization methods affect the drug formulation in different ways. Therefore, the article selected for sterilization method must be compatible with the article to be sterilized, so as to avoid damage.

In order to perform gamma or electron beam sterilization effectively, time, contact and temperature are required.

It is stipulated that the radiation absorbed dose of spices should not exceed 10kGy.

The overall average absorbed dose of irradiated pork was 0.65kGy.

The overall average absorbed dose of fresh fruits and vegetables is not more than 1.5kGy, beans are not more than 0.2kGy, and cereals are 0.4~0.6kGy; irradiation requirements: uniform irradiation, accurate dose, and unevenness of average absorbed dose ≤1.5.

The absorbed dose of tens to thousands of grays (the average radiation energy absorbed by a unit mass of material is called the absorbed dose, and the unit of gray is 1 kilogram of material absorbs 1 joule of energy, expressed in Gy, that is, 1Gy=1J/kg). It kills 90% of various bacteria and viruses (such as Escherichia coli, Salmonella typhimurium, Aspergillus niger, vaccinia virus, etc.). It can handle sealed and packaged items, easy to operate, continuous operation, and suitable for large-scale processing; It generally does not produce adverse changes, has no residual poison, and is safe and sanitary. Therefore, it has been widely used in various fields.

Common Radiation Unit Conversions:

1 Gy = 1 J/kg

1 Gy = 100 rad or 1 rad = 0.01 Gy

1 erg = 10-7 J

1 rad = 100 ergs/g or 1 erg/g = 0.01 rad

1 Mrad = 10 kGy

gamma irradiation sterilization validation

The initial acceptance must determine the dose distribution. After filling the upper and lower limits of the density range of the supplies to be irradiated with real objects or simulants whose density is similar to the real objects, the actual measurement is carried out. To determine the dose unevenness of products of different densities under different irradiation methods. The dose unevenness should not be greater than 2.

The dose deviation of the gauge dosimeter and its measuring system should be less than ±10% (at the 95% confidence level). The accuracy of the dose measurement of the reference dosimeter and its measurement system should be less than ±4% (at the 95% confidence level). When any food is irradiated, the average absorbed dose is as high as 10kGy, there will be no toxicity, and the food treated with this dose is no longer required to do toxicological experiments.

sterilization gamma ray irradiation

Gamma sterilization is a “cold” sterilization technique, where temperature is not a key parameter. Temperature may increase slightly in the product due to ionization, but gamma sterilization may be effective at ambient, refrigerated, or even frozen conditions. The key parameter is the dose received by the product. The dose is dependent on the presentation to the source and the time exposed to the gamma ray source.

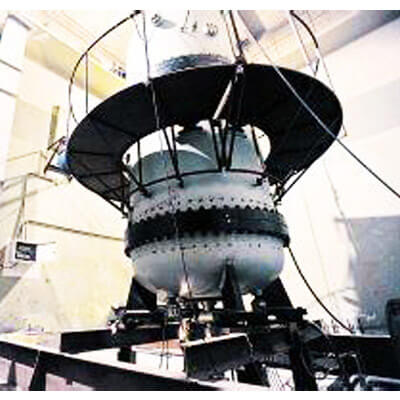

gamma ray irradiation sterilization machine

gamma irradiation sterilization machine equipment.

-

a chamber made of thick (2 m) concrete walls that prevent radiation to escape to the environment.

-

a source of ionizing radiation inside the chamber.

-

a warehouse where irradiated products are physically separated from non-irradiated products.

-

a conveyor belt that takes the products from the untreated area of the warehouse to the irradiation chamber, and then from the irradiation chamber to the treated area of the warehouse.

-

computerized systems to control the time of exposure of the products to the source of radiation.

-

safety systems that ensure that nobody can enter the irradiation chamber when it is in operation and that nobody can start operation when there is someone inside the chamber.

-

various auxiliary systems for ventilation, supply of compressed air and preservation of water quality where there is a pool.

gamma irradiation sterilization services

For many materials used to manufacture medical device and pharmaceutical components and packaging, it is possible to select and validate an appropriate and compatible industrial sterilization technique. To do so, it is important to evaluate the products’ physical limitations to select and design the proper sterilization conditions that will provide a sterile and safe product.

Radiation preservation and sterilization technology

Radiation preservation and sterilization technology is a method that uses γ, β, x-rays and electron beams generated by ionizing radiation to process products to achieve the purpose of preservation and sterilization.

Radiation Sterilization is a especial process which result can not been examined by experiment afterwards, the process controlling should be implemented in irradiation sterilization.

sterilization by gamma irradiation

irradiation of food for sterilization is usually carried out using gamma irradiation.

Radiation sterilization has strong advantages in preserving food and can be applied to the sterilization and preservation of refrigerated food in supermarkets.

Cobalt-60 is produced in power reactors around the world. It emits high-energy gamma rays and is used to eliminate harmful organisms in a variety of products: medical equipment, medicines, cosmetics, spices, consumer products, fruits, seafood, poultry, red meat, etc. .

gamma rays irradiation of foods and seeds for sterilization

Irradiated food has reached seven categories:

① Irradiation of cereals, beans and their products to kill insects;

② Insecticide and sterilization of dried fruits and preserved fruits by irradiation;

③ Irradiation preservation of cooked livestock and poultry meat;

④ Radiation preservation of frozen packaged livestock and poultry meat;

⑤ Irradiation sterilization of dehydrated vegetables, condiments, spices and tea;

⑥ Fruits and vegetables are irradiated to keep fresh;

⑦ Irradiation sterilization of fish and shellfish aquatic products, etc.

Irradiation sterilization medical products

Radiation is a safe and cost-effective way to disinfect disposable medical equipment such as syringes and surgical gloves. One of its main advantages is that it can sterilize already packaged products. All kinds of life-saving equipment have been sterilized by radiation. More than 160 gamma irradiation plants worldwide are disinfecting medical equipment. Approximately 12 million cubic meters of medical equipment are sterilized by radiation each year. More than 40% of all disposable medical devices produced worldwide are sterilized by gamma rays.

gamma irradiation sterilization process

gamma irradiation sterilization sterilization is also called gamma radiation sterilization, also called cobalt source irradiation sterilization. It uses a certain dose of ionizing rays with extremely short wavelengths to sterilize products (including raw materials). The radiation isotope cobalt 60 and cesium 157 produce γ The product is irradiated by ray or beta ray emitted by low-energy accelerator.

The gamma irradiation sterilization record includes the following:

-

a.The name, code, batch number and number of units, date of manufacture and date of receipt of the radiation sterilization supplies sent;

-

b.The loading mode of the supplies in the irradiation container or irradiation device;

-

c.The type, quantity and location of the dosimeter in the irradiation container or irradiation device;

-

d.sterilization batch number, quantity;

-

e.Radiation sterilization dose (and maximum dose);

-

f.Period timer setting;

-

g.Verified name, code, batch number and unit number of the supplies in the irradiation container;

-

h.Sterilization date;

-

i.Verified name, code, batch number and unit number of the unloaded supplies from the irradiation container or irradiation device;

-

j.Dosimeter monitoring results;

-

k.The name, code, batch number and number of units of the supplies;

-

l.Transmission equipment operation and source location, transmission channel used in the sterilization of supplies;

-

m.Sterilization treatment interruption and measures taken;

-

n.Sterilization operator's signature.