Composition of particle accelerator

Writer: Sterilization Time: 2020-09-01 Browse: 523 ℃

Basic structure of particle accelerator

Particle accelerator is a kind of complex equipment, which consists of four basic parts

(1) Grain source

For example, electron gun and ion source are used to provide charged particle beam to accelerate.

(2) Vacuum accelerating structure

Such as accelerating tube, RF accelerating cavity and annular accelerating chamber produce certain accelerating electric field in vacuum to accelerate particles.

(3) Guidance focusing system

A certain electromagnetic field is used to guide and constrain the accelerated particle beam to accelerate along a certain orbit, such as the dominant magnetic field of a circular accelerator.

(4) Beam transport and analysis system

A system consisting of electron, magnetic field lens, bent magnet and electric and magnetic field analyzer is used to transport and analyze charged particle beam between particle source and accelerator.

In addition, there are beam monitoring device, electromagnetic stability control device, vacuum device, electrical equipment and other auxiliary systems.

Composition of industrial irradiation electron accelerator

-

1. Electron gun: it is the source of electron beam.

-

2.Accelerating tube: the electron beam is accelerated by a series of direct current or pulsed electric fields.

-

3. High voltage system: it provides high voltage power source and is the most complex and valuable part of accelerator.

-

4. Electron beam extraction device: the function is to lead the electron beam out of the accelerator for irradiation.

-

5. Vacuum system: in order to avoid serious scattering between electrons and gas molecules, resulting in a large loss of beam current and energy, and even the accelerator can not work normally, a certain degree of vacuum should be maintained for normal operation of the accelerator.

-

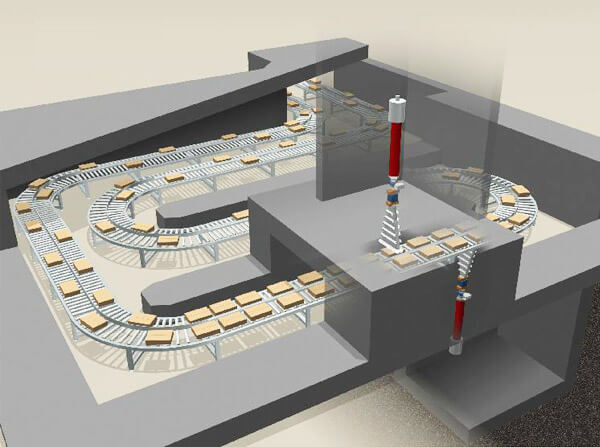

6. Under beam device: the processed products must be completed by a set of automatic flow operation equipment, which is generally called the beam under device.

-

7. Cooling system: mainly water or air cooling.

-

8. Insulating gas medium: the high-voltage generator is mainly placed in a steel barrel filled with compressed gas.

-

9. Control system

-

10. Interlocking system

Operation management of the plant

-

(1) Ensure that the device operates in good condition: operation procedures, personnel quality, regular maintenance

-

(2) The positioning accuracy of the radiation source board is as follows:

-

(3) Central position of irradiation hanging box:

-

(4) Loading position of irradiated food box:

-

(5) Correction of stay time:

Measurement and assurance of absorbed dose

(1) Adopt the meter with high accuracy, comparability and standard

(2) Metrology laboratory and bacterial test laboratory: determine the effective temperature, pressure, humidity and other environmental conditions of bacteria, pathogenic microorganisms and pests.

(3) If necessary, the radiation environment of the irradiation room shall be supervised for testing.

(4) For irradiated fresh food, the effectiveness of dose with or without respiratory peak should be determined.

Sterilization assurance level (SAL)

"Aseptic" is an absolute statement. The guarantee of sterilization for any specified object is only a probability number. The sterilization assurance level (SAL) of a product is defined as the probability that microorganisms still exist in a unit product after sterilization. En566 stipulates that the sterilization guarantee level of sterile state is 10-6, that is, only one microorganism can survive for every one million microorganisms.

Certification of radiation quality management system

ISO--9000;

ISO--14000;

ISO--11137;

Europe:

Nqabsi (UK);

TUV (Germany);

EN--552;

USA: FDA, USDA.