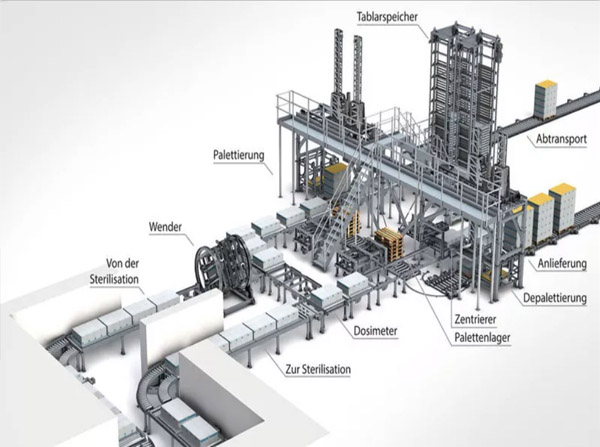

composition system of irradiation device

Writer: Sterilization Time: 2020-09-02 Browse: 793 ℃

Composition of gamma irradiation device

radiation source

Source rack and its operating system

Shielding protection system

Irradiation cargo transfer system

Control system

Dose system

Safety interlock system

ventilation system

Water treatment system

radiation source

Source rack and its operating system

Source rack is a special equipment for loading and arranging radioactive sources to form a specific radiation field. It is generally made of stainless steel.

Basic requirements for the source rack:

-

(1) The radioactive source can be safely and reliably loaded on the source rack;

-

(2) Convenient loading and unloading of radioactive sources

-

(3) Ensure that the radioactive source is not damaged by machinery;

-

(4) When the water surface is raised, the accumulated water can be drained quickly;

-

(5) The capacity of the source rack should be designed according to the maximum capacity of the device, and the annual replenishment should be properly considered;

-

(6) In order to protect the safety of the source rack, it should be equipped with a protective device to prevent the collision of the irradiators.

Common source rack types:

-

(1) Line source

-

(2) Cylindrical source

-

(3) Single board source

-

(4) Dual plate source

The radiation source is usually led out by the wire rope lifting system in the elevator.

The source elevator has the following functions:

-

(1) Positioning of the storage position of the source frame in the underground and the working position on the well

-

(2) The indication of the source frame position is given;

-

(3) Over torque protection of drive system;

-

(4) Automatic source reduction after power failure;

-

(5) Forced landing of source frame;

-

(6) Establish safety interlock centered on lifting source.

According to the driving mode, the lifting system can be divided into three types: electric, hydraulic and pneumatic. At present, pneumatic and hydraulic drive are widely used.

Shielding protection system

-

Shielding design of main protective wall in irradiation room

-

Shielding design of irradiation chamber labyrinth

-

Shielding design of irradiation room roof

-

Depth of water storage well

-

Thickness of PSD

Control system

-

(1) Control of radioactive source lifting

-

(2) Control of product transmission system

-

(3) Control of irradiation chamber door

-

(4) Remote control of intake and exhaust fans

-

(5) Signal system and intelligent voice alarm system

-

(6) Data management and monitoring system

Safety interlock system

The gamma irradiation device must be equipped with a safety interlock system with complete functions and reliable performance, especially for effective monitoring and interlocking of personnel and goods access, source rack operation system, cargo transmission system, etc. The safety interlock system is composed of physical devices, mechanical or electrical facilities, and depends on the interlocking design of automatic control system.

Radiation safety dose monitoring of dose system

-

① Dose monitoring in radiation workplace

-

② Personal dose monitoring of staff

-

③ Monitoring of radioactive contamination in storage well water and cobalt source transport container

Measurement of dose field in irradiation room

Measurement of absorbed dose of irradiated products

Control of poisonous gas in ventilation system

Radiolysis can produce ozone, nitrogen oxides and other toxic gases. Measures need to be taken to prevent personnel from being exposed to toxic gases that exceed the concentration limits set by relevant audit and management departments.

Ventilation system which can produce negative pressure in irradiation chamber is usually used.

Air flow is continuously measured and radiation is automatically terminated in the event of system failure. Time delay interlock is usually applied.

Water treatment system

At present, most of the gamma irradiation devices adopt wet source storage system. The water storage well foundation is made of waterproof concrete and lined with stainless steel cladding. In order to prevent the impurities in water from corroding the radioactive source, the source well water should be deionized water or distilled water.

Water quality required conductivity: 1 ~ 10 μ s / CMP

H value: 5.5 ~ 8.5

Chlorine (CL) ion: ≤ 1ppm.